Specialty machinery for making tires puts firm at front of pack

Editor's note: This series of stories looks at local enterprises in specialized sectors that have a share in global markets.

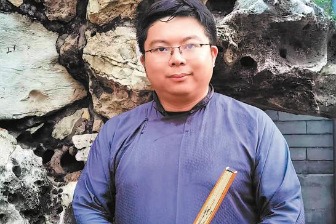

Technology manager Li Bin described the difficulties faced by the factory where he works when, well before his time, it made key machines used in car tire production. "It took many of us to work on just one rubber extruder as it rolled off the production line," he said.

The company "had to smooth out many kinks in the manufacturing process," Li said. "We had to rely on imported equipment and expertise, learning step by step. It was a bumpy road at the beginning."

Rubber extruders are crucial machinery that manufacturers use to shape rubber materials into specific products.

Fast-forward four decades, and the company for which the 39-year-old Li works, China Chemical Guilin Engineering-which is based in Guilin, a city in South China's Guangxi Zhuang autonomous region-is now a leading manufacturer of the high-precision tire-making machines.

Li, summing up the company's formula for success, said that, as in many places nationwide that have emerged as hubs of specialized sectors led by pole players, a major focus on research and development, innovation, skills training, a strong work ethic and pursuit of excellence were required to become globally competitive.

"Just 10 years ago, we still came across equipment from Germany supplied to tire makers in markets like Turkiye," said Li, who heads the group's research and development team. "Last year, our rubber extruders also found their way there. Overseas high-end tire manufacturers now favor our equipment because of its quality and value."

Key advantages

The company said its advanced Quituplex rubber extruder machines, which form a pivotal part of the tire production process in which composite material is ejected and channeled via precision molds, has been integral in moving the company to the forefront of the industry. Its efficiency and quality have improved significantly, with labor costs reduced by at least one-fifth, the company said.

The state-of-the-art extruders were rolled out by the Guilin production line in 2015 after years of intensive development, making the company "the only domestic one of its kind and part of a handful of others worldwide that can design and build such high-end equipment on their own", according to the company.

According to the company, which has nearly 500 skilled workers at home and abroad, the extruders-which can sell for about 20 million yuan ($2.9 million) each-h(huán)ave become its main export product.

The sales volume of Quituplex extruders and related parts and equipment has hit 1.03 billion yuan since 2015, ranking it first in its field, the company said.

Growth potential remains bright. The company recorded total output value of 950 million yuan last year, with almost half of its extruder production, or 87 out of 185 units that it made, heading to countries around the world including Canada, Brazil, Poland, India, Malaysia and Australia.

As part of the latest efforts to tap global infrastructure and development opportunities under the Belt and Road Initiative, the company has also launched a major tire production base in Thailand. Covering about 58 hectares, and with a production scale of about 12 million standard passenger car radial tires a year, the overseas facility is the largest of its kind, according to the company.

The group's nationwide presence includes bases in financial hub Shanghai and regional capital Nanning, all helping to build on its numerous industry patents and achievements, in line with the region's development strategies and priorities.

Xu Wenwei, deputy director of the Guangxi market supervision authority and director of the regional intellectual property office, said that looking ahead, Guangxi "will highlight high-quality growth, cultivate high-value patents and intellectual property talent, seize new development opportunities presented by the Regional Comprehensive Economic Partnership free trade agreement, and build a higher level of cooperation for enterprises".

Meeting new demands

Zhang Tong, a top executive at China Chemical Guilin Engineering who has 30 years' experience in the sector, said that riding the latest trends and meeting new demands continue to be integral to success, such as utilizing environmentally friendly materials in green production and using automation and artificial intelligence in logistics and supply chains.

"Amid the pandemic, we saw an increase in the demand for logistics vehicles and, as such, their tires. Low-end, smaller producers became less competitive, giving rise to the major players, who lead with better quality and capabilities to further tap the latest opportunities for expansion at home and beyond," Zhang said.

The company's green approach is in line with its host city's emphasis on sustainable development. Guilin increasingly invests in preserving, protecting and promoting its environmental attractions. The tourism, beverage, textile and other pillar sectors bank on the clear waters of the city's Lijiang river and beautiful karst landscape.

The latest green projects at the tire equipment maker include the development of rubber, plastic, chemical and other products that tap into energy-saving, carbon-reducing, renewable energy and efficiency enhancing technologies. Production lines have been further automated and are AI-enabled, and the company has demonstration devices for the recycling of waste tires.

Zhang said the company benefited from major investments in sustainable materials, technology and processes when the industry had to cater to European standards calling for the production of environmentally friendly tires a decade ago.

"The company's current challenge is still to strengthen research and development. Investment in that area hit 40 million yuan last year. Attracting high-end talent remains challenging," Zhang said. "We are pushing ahead to plug that, leveraging incentives and policies to accelerate and gear up growth."

- Octogenarian honored in Chongqing for five decades of relic preservation

- Yunnan's white plum blossoms create a cozy counter to the seasonal chill

- Sichuan prefecture launches lifetime scenic spot passes to attract tourists

- Authorities warn against abuse of consumer complaint system

- Chinese scientists develop breakthrough ABF crystal, strengthening global lead in VUV technology

- China to boost social assistance for vulnerable groups during Spring Festival holiday