Sany's Indonesia plant a major milestone

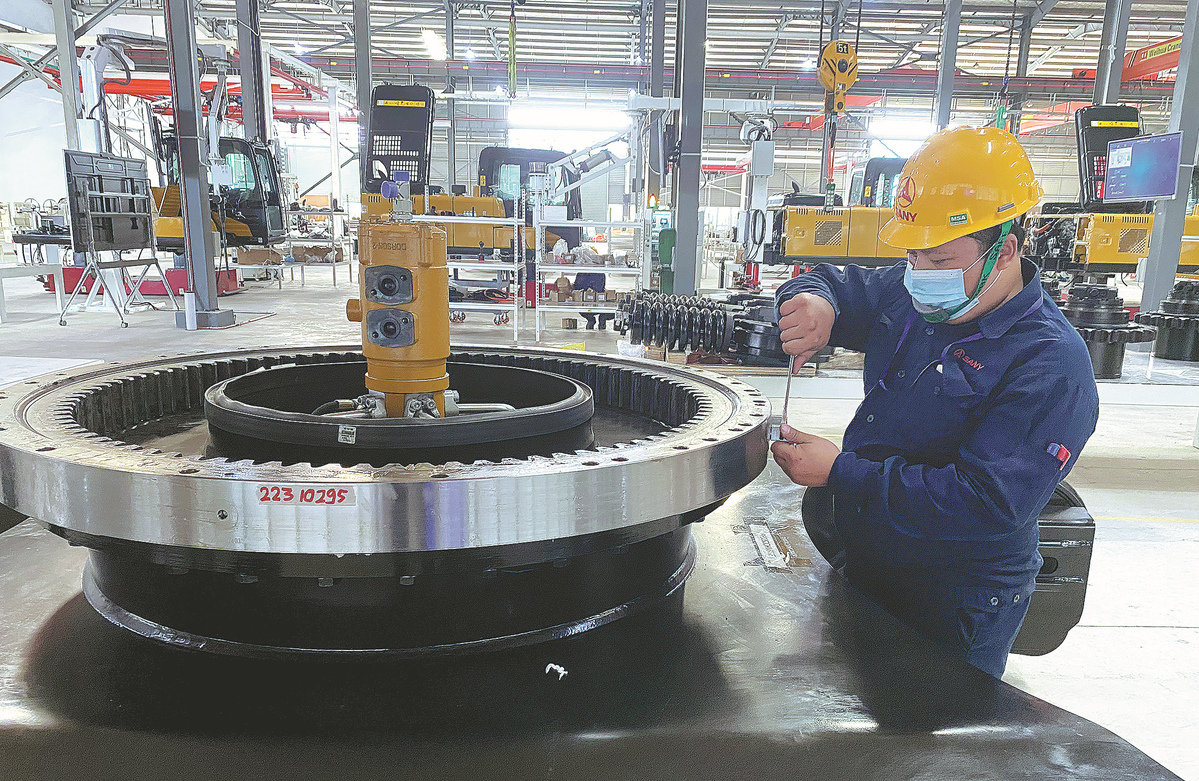

Chinese machinery enterprise realizes smart manufacturing with key 'lighthouse factory'

Through the establishment of an overseas "lighthouse factory", Chinese machinery giant Sany Group is exporting Chinese mechanical wisdom to the world.

On Aug 15, the first excavator produced by Sany's lighthouse factory in Indonesia was put into operation, marking the first overseas footprint of such a plant for China's machinery industry.

"Lighthouse factories" are the most advanced factories, which are leading the way in the adoption and integration of frontier technologies around the world. The World Economic Forum and global market research firm McKinsey & Co jointly issued a lighthouse factory list, which selects such factories.

Sany began the lighthouse factory transformation on 20 plants in 2019. It has so far spent over 10 billion yuan ($1.45 billion) and established over 40 lighthouse factories in China, realizing a real-time interconnection of nearly 10,000 sets of equipment and more than 100,000 types of materials. The lighthouse factory in Indonesia was the group's first of its kind overseas.

Xu Ming, senior vice-president of Sany Heavy Industry Co Ltd and president of Sany International Operation Headquarters, said: "The establishment of the lighthouse factory in Indonesia brings advanced manufacturing technology to the country, shares professional technical knowledge, accelerates the cultivation and reserve of local talent and creates employment opportunities. More importantly, by cooperating with local component makers and developing new products, we will further improve our supply capacity of spare parts and offer customers a more complete one-stop experience.

"Having the first overseas lighthouse factory established in Indonesia will help us expand our business in the rest of the ASEAN, as well as countries including Australia and New Zealand. The lighthouse factory is expected to promote the high-quality development of Indonesia's machinery industry, and contribute to the construction of the Belt and Road Initiative," Xu said.

The company's lighthouse factory is located in the KIM Industrial Park in Indonesia, which is 70 kilometers from the capital city of Jakarta. With a total investment of 200 million yuan, the expected annual capacity of the first phase of the factory is 3,000 excavators.

In July, the first batch of equipment produced by the lighthouse factory in Indonesia was approved by local authorities. Within 30 days, the first excavator made in Indonesia was put into operation.

Currently, the factory has realized the whole network connection and unmanned production of 12 main procedures, including assembly, logistics and commissioning, creating a precedent for Chinese enterprises' overseas manufacturing.

"This lighthouse factory combines the core achievements of Sany's over 40 domestic lighthouse factories, and is the first overseas manufacturing base established totally based on the Industry 4.0 standard of China's machinery industry," said Ding Shifeng, assistant vice-president of the Indonesia project department of Sany Heavy Industry.

Ding said there are over 500 robots of various types in the factory, with only around 100 workers. The expected annual output value per capita is 11 million yuan, making the factory one of the most intelligent factories with the highest output value per capita overseas.

Compared with Sany's overseas bases in the United States, Germany, India and Brazil, the lighthouse factory in Indonesia, for the first time, relies on 100 percent of its independent intellectual property.

"This is the first overseas systematic output of intelligent manufacturing of China's machinery industry," Ding said.

Of the 50 Smartest Companies listed by international tech media MIT Technology Review, Sany Heavy Industry became the only Chinese machinery enterprise listed to make the cut.

Ding, who is in charge of Indonesia's lighthouse factory project, said that construction of the project demonstrated the unity and cohesion of Sany's employees.

"Last July, when the project just began, we found that some tools that were used to unload goods and to install the machines were not completely ready. They were difficult to import from China due to policy restrictions. Our grassroots staff all acted positively to work out solutions, immediately went to hardware stores nearby and contacted local suppliers to purchase what we urgently needed," he said.

"Every worker regarded the project as the most important undertaking of their own. One night, the team was unloading goods and encountered time-consuming equipment commissioning. I had an important schedule the other day and went to the dorm at midnight. However, when I woke up, I found that the entire team had worked through the night and had continued until noon to finish the commissioning.

"This is the corporate culture of Sany. Employees are satisfied only when the task is completed," Ding said.

The company said that the little step taken by the lighthouse factory in Indonesia was a great step forward for Sany's overseas manufacturing.

"The establishment of the factory is expected to change the world's impression of China's intelligent manufacturing. It offers a great opportunity for the world to know about the fact that China's intelligent manufacturing, to some extent, is taking the lead position in the world," Ding said.

Xu said: "The lighthouse factory greatly demonstrates that Sany's intelligent manufacturing is at the forefront of the machinery industry in the world. Through advanced technologies, our production rate increased by 85 percent, while the production period was cut from 30 to seven days. More importantly, our manufacturing standard was raised, and product quality took a qualitative leap."

Chen Jia, an independent researcher in international strategy, said: "The launch of Sany's lighthouse factory in Indonesia marks that China's machinery industry is going global, and further solidifies the foundation development of the BRI."

"With Sany setting a great example, it is expected that Chinese enterprises will get involved with more BRI-related projects, and they will actively invest in countries and regions involved in the BRI with higher standards," said Liang Haiming, dean of the Hainan University Belt and Road Research Institute.

To boost the local manufacturing level and offer talent cultivation to support the local society, Sany also built a training center in Indonesia that accommodates over 600 people at the same time.

The company said that in the future, it will use the lighthouse factory in Indonesia as a template to quickly promote and replicate within the company and build 10 more such factories overseas in the coming years.

"Our overseas journey has just started. Facing mounting challenges in the world, Sany is fully prepared. We will spare no effort to become a world-leading company," Xu said.

Data from Sany Group showed that in the first half, the group's overseas sales revenue surged by nearly 40 percent year-on-year, among which sales revenue from the United States, Europe and Southeast Asia doubled.

During the same period, the market share of its pump and pedrail cranes topped the world. Overseas sales of its excavators increased by nearly 70 percent year-on-year, the company said.